Différentiel de Cutlass 1977 (8.5)

4 participants

Page 1 sur 1

Différentiel de Cutlass 1977 (8.5)

Différentiel de Cutlass 1977 (8.5)

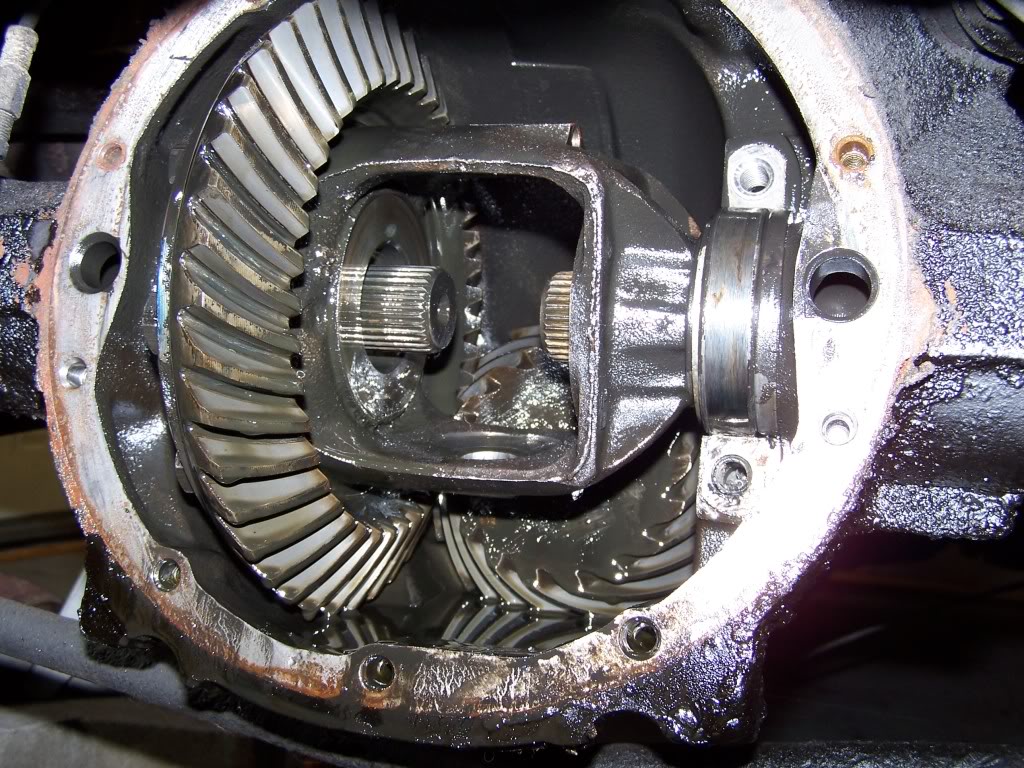

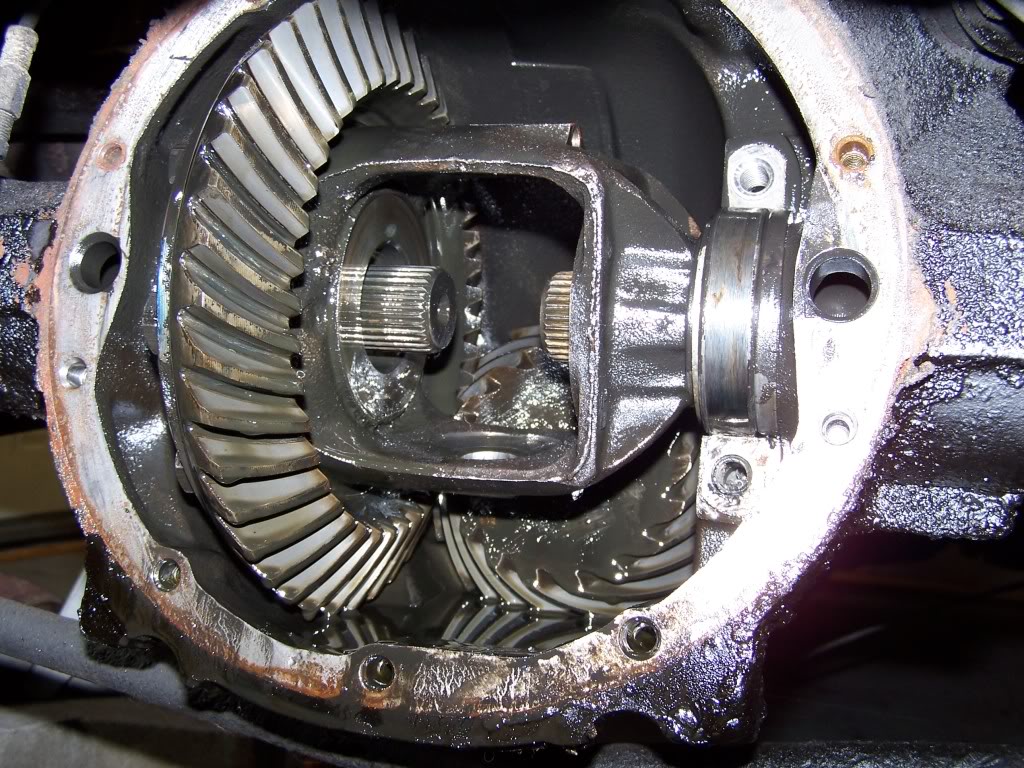

Bon ben, après 3 mois, je suis enfin retourné dans le garage et commencer a démonter le différentiel. Après avoir sacré pendant 15 minute avec la pin cassée en deux dans le trou, j'ai réussi a démonter mais là j'ai un petit problème car je m'attendais a trouver des c-clips pour les essieus mais y en a pas  Ça semble pas vouloir sortir de là pis je veux pas varger dessus non plus. Helllllllllllllllllp

Ça semble pas vouloir sortir de là pis je veux pas varger dessus non plus. Helllllllllllllllllp

cut77- Amateur

- Date d'inscription : 18/12/2009

Re: Différentiel de Cutlass 1977 (8.5)

Re: Différentiel de Cutlass 1977 (8.5)

Voici 2 photo du diff... Normalement on vois les clips sur le bout des essieus mais la y en pas  pis ça sort pas :

pis ça sort pas :

pis ça sort pas :

pis ça sort pas :

cut77- Amateur

- Date d'inscription : 18/12/2009

Re: Différentiel de Cutlass 1977 (8.5)

Re: Différentiel de Cutlass 1977 (8.5)

REMOVAL & INSTALLATION

Two types of axles are used on these models, the C-lock and the non C-lock type. Axle shafts (in the C-lock type) are retained by C-shaped locks which fit grooves at the inner end of the shaft. Axle shafts in the non C-lock type are retained by the brake backing plate, which is bolted to the axle housing. Bearings in the C-lock type axle consist of an outer race, bearing rollers, and a roller cage retained by snaprings. The non C-lock type axle uses a unit roller bearing (inner race, rollers, and outer race), which is pressed onto the shaft up to a shoulder. When servicing C-lock or non C-lock type axles, it is imperative to determine the axle type before attempting any service. The best way to do this is to remove the axle carrier cover and visually determine if the axle shafts are retained by C-shaped locks at the inner end, or by the brake backing plate at the outer end.

--------------------------------------------------------------

CAUTION

Since the brake shoes will be exposed as you perform this procedure, note that some brake shoes contain asbestos, which has been determined to be a cancer causing agent. Never clean the brake surfaces with compressed air! Avoid inhaling any dust from any brake surface! If you have to clean the brake shoes, use a commercially available brake cleaning fluid to remove any brake dust first.

Non C-Lock Type

See Figure 1

-------------------------------------------------------------------

CAUTION

Before attempting any service to the drive axle or axle shafts, remove the differential carrier cover and visually determine if the axle shafts are retained by C-shaped locks at the inner end, or by the brake backing plate at the outer end. If the shafts are not retained by C-locks, proceed as follows.

-----------------------------------------------------------------------

Design allows for maximum axle shaft end-play of 0.022 in. (0.558mm), which can be measured with a dial indicator. If end-play is found to be excessive, the bearing should be replaced. Shimming the bearing is not recommended as this ignores end-play of the bearing itself and could result in improper seating of the bearing.

1= Remove the wheel, tire and brake drum

Fig. Fig. 1: Breaking the bearing retainer with a chisel

2= Remove the nuts holding the retainer plate to the backing plate. Disconnect the brake line.

3= Remove the retainer and install the two lower nuts finger-tight, to prevent the brake backing plate from being dislodged

4= Pull out the axle shaft and bearing assembly, using a slide hammer.

5= Using a chisel, nick the bearing retainer in three or four places. The retainer does not have to be cut, merely collapsed sufficiently to allow the bearing retainer to be slid from the shaft.

6= Press off the bearing and install the new one by pressing it into position.

Do not attempt to press the bearing and the retainer on at the same time.

7= Assemble the shaft and bearing in the housing, being sure that the bearing is seated properly in the housing.

8= 8.Install the retainer, drum, wheel and tire. Bleed the brakes.

SOURCE: AUTOZONE.COM

Two types of axles are used on these models, the C-lock and the non C-lock type. Axle shafts (in the C-lock type) are retained by C-shaped locks which fit grooves at the inner end of the shaft. Axle shafts in the non C-lock type are retained by the brake backing plate, which is bolted to the axle housing. Bearings in the C-lock type axle consist of an outer race, bearing rollers, and a roller cage retained by snaprings. The non C-lock type axle uses a unit roller bearing (inner race, rollers, and outer race), which is pressed onto the shaft up to a shoulder. When servicing C-lock or non C-lock type axles, it is imperative to determine the axle type before attempting any service. The best way to do this is to remove the axle carrier cover and visually determine if the axle shafts are retained by C-shaped locks at the inner end, or by the brake backing plate at the outer end.

--------------------------------------------------------------

CAUTION

Since the brake shoes will be exposed as you perform this procedure, note that some brake shoes contain asbestos, which has been determined to be a cancer causing agent. Never clean the brake surfaces with compressed air! Avoid inhaling any dust from any brake surface! If you have to clean the brake shoes, use a commercially available brake cleaning fluid to remove any brake dust first.

Non C-Lock Type

See Figure 1

-------------------------------------------------------------------

CAUTION

Before attempting any service to the drive axle or axle shafts, remove the differential carrier cover and visually determine if the axle shafts are retained by C-shaped locks at the inner end, or by the brake backing plate at the outer end. If the shafts are not retained by C-locks, proceed as follows.

-----------------------------------------------------------------------

Design allows for maximum axle shaft end-play of 0.022 in. (0.558mm), which can be measured with a dial indicator. If end-play is found to be excessive, the bearing should be replaced. Shimming the bearing is not recommended as this ignores end-play of the bearing itself and could result in improper seating of the bearing.

1= Remove the wheel, tire and brake drum

Fig. Fig. 1: Breaking the bearing retainer with a chisel

2= Remove the nuts holding the retainer plate to the backing plate. Disconnect the brake line.

3= Remove the retainer and install the two lower nuts finger-tight, to prevent the brake backing plate from being dislodged

4= Pull out the axle shaft and bearing assembly, using a slide hammer.

5= Using a chisel, nick the bearing retainer in three or four places. The retainer does not have to be cut, merely collapsed sufficiently to allow the bearing retainer to be slid from the shaft.

6= Press off the bearing and install the new one by pressing it into position.

Do not attempt to press the bearing and the retainer on at the same time.

7= Assemble the shaft and bearing in the housing, being sure that the bearing is seated properly in the housing.

8= 8.Install the retainer, drum, wheel and tire. Bleed the brakes.

SOURCE: AUTOZONE.COM

Dernière édition par Chevy75 le 28/2/2010, 14:53, édité 2 fois (Raison : ajouté la source)

Chevy73- Modérateur

- Date d'inscription : 10/10/2009

Re: Différentiel de Cutlass 1977 (8.5)

Re: Différentiel de Cutlass 1977 (8.5)

En passant Cut peut tu me dire si tu va avoir un differentiel de spare .....ca me donne le gout pour mon Chevelle un non c-clip type......

Chevy73- Modérateur

- Date d'inscription : 10/10/2009

Re: Différentiel de Cutlass 1977 (8.5)

Re: Différentiel de Cutlass 1977 (8.5)

Merci Chevy75 pour les explications  J'ai essayer mon sledgehammer mais il n'est pas adapté et ça fitte pas et comme j'ai vu sur un autre site, ils sont bien pris alors je vais m'amuser

J'ai essayer mon sledgehammer mais il n'est pas adapté et ça fitte pas et comme j'ai vu sur un autre site, ils sont bien pris alors je vais m'amuser  Le pire c'est que j'hésite encore pour ma gear... 3.08, 3.23 ou 3.43

Le pire c'est que j'hésite encore pour ma gear... 3.08, 3.23 ou 3.43  et je ne veut pas démonter plusieurs fois avec le genre ce genre de setup là. A suivre....

et je ne veut pas démonter plusieurs fois avec le genre ce genre de setup là. A suivre....

J'ai essayer mon sledgehammer mais il n'est pas adapté et ça fitte pas et comme j'ai vu sur un autre site, ils sont bien pris alors je vais m'amuser

J'ai essayer mon sledgehammer mais il n'est pas adapté et ça fitte pas et comme j'ai vu sur un autre site, ils sont bien pris alors je vais m'amuser  Le pire c'est que j'hésite encore pour ma gear... 3.08, 3.23 ou 3.43

Le pire c'est que j'hésite encore pour ma gear... 3.08, 3.23 ou 3.43  et je ne veut pas démonter plusieurs fois avec le genre ce genre de setup là. A suivre....

et je ne veut pas démonter plusieurs fois avec le genre ce genre de setup là. A suivre....

cut77- Amateur

- Date d'inscription : 18/12/2009

Re: Différentiel de Cutlass 1977 (8.5)

Re: Différentiel de Cutlass 1977 (8.5)

Chevy75 a écrit:En passant Cut peut tu me dire si tu va avoir un differentiel de spare .....ca me donne le gout pour mon Chevelle un non c-clip type......

Ouaip. le 442 pour pièce a le même kit. On s'en reparle cet été

cut77- Amateur

- Date d'inscription : 18/12/2009

Re: Différentiel de Cutlass 1977 (8.5)

Re: Différentiel de Cutlass 1977 (8.5)

As tu un zipgun ?

Si oui

As tu un marteau pour mettre dessus ?

La vibration y'as rien de tel pour decoller de quoi

donne de la vibration sur la flange qui retiens la backplate, avec la vibration ca devrait decoller, normalement ce type de differentiel les essieu sorte sans forcer.

Si oui

As tu un marteau pour mettre dessus ?

La vibration y'as rien de tel pour decoller de quoi

donne de la vibration sur la flange qui retiens la backplate, avec la vibration ca devrait decoller, normalement ce type de differentiel les essieu sorte sans forcer.

Dernière édition par Chevy75 le 28/2/2010, 15:39, édité 1 fois (Raison : correction)

Chevy73- Modérateur

- Date d'inscription : 10/10/2009

Re: Différentiel de Cutlass 1977 (8.5)

Re: Différentiel de Cutlass 1977 (8.5)

cut77 a écrit:Chevy75 a écrit:En passant Cut peut tu me dire si tu va avoir un differentiel de spare .....ca me donne le gout pour mon Chevelle un non c-clip type......

Ouaip. le 442 pour pièce a le même kit. On s'en reparle cet été

Pas de probleme j'attend

Chevy73- Modérateur

- Date d'inscription : 10/10/2009

Re: Différentiel de Cutlass 1977 (8.5)

Re: Différentiel de Cutlass 1977 (8.5)

Finalement, avec un peu de patience pis un drum a l'envers, ça fini par sortir Sauf que je ne ferais pas trop d'essais avec ce genre de setup pour ma nouvelle gear...

cut77- Amateur

- Date d'inscription : 18/12/2009

Re: Différentiel de Cutlass 1977 (8.5)

Re: Différentiel de Cutlass 1977 (8.5)

Ca a l air d un jeu amusant ...

Faut un garage large

Tu as decidé comment des gears a monter pour ton usage ?

Et quel usage ?

Street ? Promenade ? Autoroute ?

Faut un garage large

Tu as decidé comment des gears a monter pour ton usage ?

Et quel usage ?

Street ? Promenade ? Autoroute ?

nali- Accro

- Date d'inscription : 18/10/2009

Re: Différentiel de Cutlass 1977 (8.5)

Re: Différentiel de Cutlass 1977 (8.5)

nali a écrit:Ca a l air d un jeu amusant ...

Faut un garage large

Tu as decidé comment des gears a monter pour ton usage ?

Et quel usage ?

Street ? Promenade ? Autoroute ?

Pour le garage...Il a seulement 14 pieds de large et je ne suis toujours pas décidé pour ma gear et pour l'usage, se seras promenade et street car on n'a pas d'autoroute en Abitibi

cut77- Amateur

- Date d'inscription : 18/12/2009

Re: Différentiel de Cutlass 1977 (8.5)

Re: Différentiel de Cutlass 1977 (8.5)

C est quoi le gear a l origine ?

Mon Delta c est 2.41 . Ca spinne pas trop d origine

Mon Delta c est 2.41 . Ca spinne pas trop d origine

nali- Accro

- Date d'inscription : 18/10/2009

Re: Différentiel de Cutlass 1977 (8.5)

Re: Différentiel de Cutlass 1977 (8.5)

nali a écrit:C est quoi le gear a l origine ?

Mon Delta c est 2.41 . Ca spinne pas trop d origine

Même chose pour moi et c'est pouquoi je change

cut77- Amateur

- Date d'inscription : 18/12/2009

Sujets similaires

Sujets similaires» oldsmobile cutlass 1977

» Olds Cutlass 442 1977, moteur 403

» L'enfer du différentiel

» differentiel

» differentiel

» Olds Cutlass 442 1977, moteur 403

» L'enfer du différentiel

» differentiel

» differentiel

Page 1 sur 1

Permission de ce forum:

Vous ne pouvez pas répondre aux sujets dans ce forum

S'enregistrer

S'enregistrer